High-speed Rail / Bullet Train projects, WINSTEEL has designed, manufactured, and supplied bridge building equipment like Full Span Mould / Box Girder Mould, Pier & Pier cap Formworks & Long Line Moulds and many more.

Hight Speed Rail

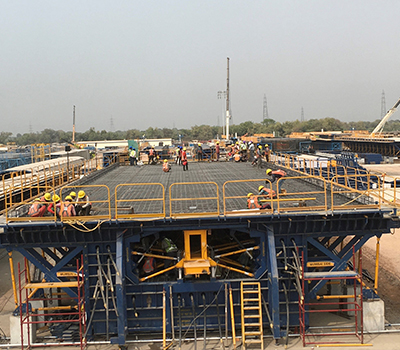

The Full Span Mould from WINSTEEL was successfully used to cast the first Full Span Box Girder of 40m length ever made in India. The Full Span Moulds are entirely hydraulically operated, including the operations of the outer Forms, which shortens the cycle time and requires less labour. Inner Form has one of the fastest and smoothest self-propelling systems. Modern technologies are integrated into hydraulic systems to track hydraulic operations and lower maintenance and breakdown costs.

WINSTEEL also have Designed, manufactured & supplied of Variable full Span mould like 36~40m Span, 31~35m Span & full span 31~40m.

Our contribution to the construction of high-speed rail projects can range from the pile cap to launching gantries, bridge gantries, straddle carriers, transporters, and other components. These components are in addition to the pier and pier formworks, long line moulds, river Span moulds, and full Span moulds.

WINSTEEL’s Pier & Piercap Formworks include optimised weight, simplicity of handling, specified lifting location, quick assembly and de-shuttering, integrated climbing system, safety, and super finish quality of concrete surfaces.

WINSTEEL Designs, Manufactures & Supplies Long Line & Short Line Moulds, which has the quickest cycle time with the fewest elements. Winsteel solution for the mould is most optimized and cost effective to match the project timeline and designed as per casting yard area availability. The operation of the mould have all the options of mechanical, semi-automatic and fully automatic systems: which reduces the man power requirement, operating time and thus gives the best productivity of the mould.